IoT Gateway

IoT Gateways are intelligent central hubs that enable connectivity for the Internet of Things (IoT) devices. They connect IoT devices with limited computing and storage to the cloud, where end-user applications manage and use data.

Industrial IoT Gateway

An Industrial IoT Gateway runs powerful OS like Embedded Linux, Android & WinCE, supporting multiple Industry standard wireless ZigBee, Bluetooth Low Energy (BLE), 6LoWPAN & IEEE 802.15.4 MAC. It communicates with Sensor Network and other end reliable communication channels WiFi, Ethernet, 2G & 3G GSM/CDMA to connect to the cloud & also can be used as a stand-alone private cloud server by running MQTT (OASIS standard messaging protocol for IoT devices) Broker and local Database with tiny feature-rich Web servers. The IoT Gateway includes CAN bus ports, Digital I/Os, Protected USB, and serial Ports.

In many industries, there tends to be a large amount of legacy equipment that is installed without any means of connectivity to analyze the possible data they can provide, which leaves a lot of potentially valuable data locked away in an array of equipment. IoT Gateways are designed to securely connect to the internet/cloud using WiFi, LAN, or cellular communication, and this connectivity provides a solution to unlock meaningful data from these legacy devices.

Features of Industrial IoT Gateway

- Compact design

- Connectivity, Data Collection, and Communication

- Rich connectivity options

- Exceptional security

- Real-Time Processing and Decision Making

- Condition Monitoring

- Production Monitoring

- Remote monitoring

- Preventive maintenance

- Production optimization

- Building automation

- Easily Programmable PYTHON/JAVA/C++/C

- Customize Hardware & Software for Application requirements

- CE/FCC Compliances with Industrial-Grade Designs

- Flexible power input

- High energy efficiency

- Industrial-grade components

- Fail-proof shock and vibration resistance

- Wide temperature range

Applications:

- Industry 4.0

- Factory Automation

- Retail Automation

- Smart Agriculture

- Smart Transportation

- Intelligent Transportation System

- Building Automation & Security

- Utilities

- Railway

- Logistic Automation

- Power & Energy

- Energy Monitoring

- Oil & Gas

- Medical and Healthcare

- Monitoring & Control Systems

- Surface And Underground Mining

Functions of Industrial IoT gateways

-

1. Easy communication and control with flexible I/O

IIoT gateways provides an easy path of communication between IoT and other electronic devices. They enable one type of device or a machine to interact with other machines, environments, devices, and appliances.

IIoT gateways support most industrial protocols like PROFIBUS, EtherCAT, Fieldbus, PROFINET, and Ethernet/IP, which help connect different types of devices.

Suppose a company has legacy hardware that cannot be connected to the cloud. In such cases, industrial IoT gateways help them connect to the cloud and allow them to control devices, machinery and programmable logic controllers securely and remotely. -

2. Real-time processing and decision-making

Industrial IoT gateways gather and study data collected locally at the installed location and in real time. IIoT Gateways provide convenience because such applications use the data within the site instead of sending it to a remote machine to process, analyze or report.

The Gateway dealing with critical workloads can instantly get key insights from the data and apply appropriate solutions, thereby improving decision-making. There are no latency associated with sending, processing, and sending the data back to an industrial setting in IIoT Gateway, which also means real-time data analysis and decision-making within millisecond is possible. -

3. Boosted efficiency in production

IIoT gateways can help improve factory production by collecting information from various sensors and devices deployed on the premises. The data can fine-tune the production process for efficient and higher output.

The whole process can reduce human error and collect a wide variety of data related to the manufacturing process. The information helps operators and organizations in optimizing their production lines. -

4. Facilitation of predictive maintenance in manufacturing

The data gathered in IIoT Gateways by sensors and devices can be efficiently used by the IIoT Gateways to predict when a component or a device in a factory is malfunctioning or could typically fail.

IIoT gateways apply prediction models to schedule maintenance before the breakdown occurs. Production lines operate 24/7. Failure of a machine or a component can halt production, causing a delay in the overall manufacturing process and customer deliveries which may result in loss.

But thanks to the insights provided by the IIoT gateways, factories can comfortably reduce or eliminate the costs associated with unexpected downtime detrimental to the production process. -

5. Communication With The Cloud

IIoT Gateways can easily communicate with the cloud. It’s a critical role. The gateway connects the sensor layer and the cloud using Wi-Fi, 4G, or 5G. The communication is bilateral: the raw data from devices go to the cloud, and commands go the opposite. IoT devices that don’t support the internet connection can get it via IIoT gateways. IIoT Gateways provide Centralized dataflow control and Monitor IoT fleet. It can also be used for remote control over the IoT fleet.

-

6. Supports multiple transfer protocols

Sensors use low-power, short-range communication protocols such as Bluetooth Low Energy, ZigBee, Radio Frequency Identification (RFID), LoRaWAN, or medium-long range protocols like Wi-Fi and LoRa. The gateway, in turn, transfers the data through more power-intensive protocols like cellular wireless/LTE and Ethernet. However, the gateway should support all protocols to ensure communication. All devices speak in different languages. The IoT gateway facilitates their communication.

-

7. Aggregation and preprocessing of the data

The gateway may have the local data processing power to aggregate, filter, summarize, and cluster gathered data before passing it ahead. IIoT Gateways have configurations that handle some typical issues and provide instant responses to IoT devices. IIoT Gateways reduces the overall data flow, lower data transmission costs, and improves response time to IoT gadgets.

-

8. Security

IoT devices often demonstrate low-security levels. Security has become the primary necessity in this day and age. IIoT Gateways have become a practical solution, with essential security mechanisms like TPM 2.0, advanced encryption, and unauthorized access control. IIoT Gateways provide improved security and prevent the diversion of sensitive data during transfer. IIoT Gateways block unauthorized connections outside the IoT ecosystem.

-

9. Local storage of data

Gateways feature enough local storage capacity to cache data when disconnected from the cloud. All information remains safe and sound. IoT gateways assume responsibility for almost a dozen functions – we expect them to be smart enough to operate effectively. They are smart indeed, thanks to the custom software they possess.

Industrial IoT Gateway devices

1. Gateway Konnect

Gateway Konnect allows various vertical markets to leverage IoT technologies, including cloud services, big data, and even artificial intelligence, to connect machine controllers, sensors, instruments, and other devices into an easily controlled and managed network solution. Gateway Konnect provides that connection between the sensor and the cloud, usually being the first system-level device in the IIoT chain of communication. AAEON Industrial IoT Gateways provide broad and flexible I/O layouts capable of interfacing with the most common industry standards.

Features

- Wifi & Bluetooth

- Real-Time Data

- Remote Data Access

- Evolve Integrated

- Modbus or RS 232

- Digital input & Digital output

Application

- PLC | HMI | IO Cards

- Energy Meter

- Water Meter

- Sensors & Devices

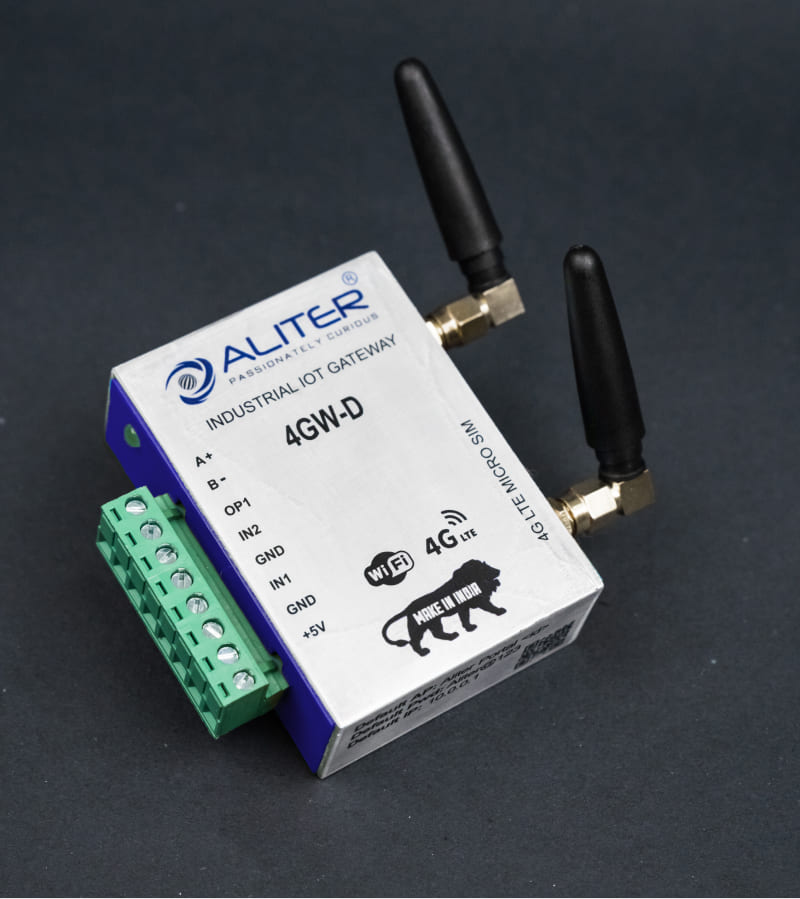

2. Gateway 4GW-D

Aliter IIoT 4GW–D Gateway is the industry’s smallest and most affordable device, which can be seamlessly integrated into a wide range of machines and meters used in various industries. The process of manual data capturing can be automated with the installation of IIoT Gateway.

Features

- Smallest and most affordable

- Realtime Monitoring

- Remote Network Config

- Remote Modbus Config

- Easy to install

- Machine, Network, and Software Integration Support

Applications

- CNC OEE

- Injection Moulding OEE

- Energy Monitoring

- PLC Process Parameter

- Monitoring

- Weighing Scale Data Capture

- Solar Inverter Monitoring

- VFD Monitoring

- Liquid Analyser